RFL-P20QE/A3/115/2

20W FIBER LASER CABINET MODEL

Fiber Lasers are the preferred tool whatever material is used to produce permanent markings with high accuracy at high speed with a contactless process. Laser marking does not require consumables. Marks are produced on the computer and are therefore extremely flexible. Our products provide a long and maintenance-free service life

Some of the uses of fiber laser markers that serve a very wide industrial area are as follows:-

· Semiconductor industry: Used to mark small silicon materials used in almost all electronics.

· Aerospace Industry: Used to mark thousands of different tracks forming a plane.

· Automotive Industry: Used in the automotive industry, just like aviation, to mark thousands of different parts forming a land vehicle.

· Medical Industry: Used to create identification marks easily traceable on medical equipment.

· Electronic Sector: It is used for making markings on endless variety of materials such as protective bodies of these parts, except for the semiconducting components which make up electronic parts.

Every effort has been made in the course of the planting.

· Focussing on the smallest areas: Makes perfect marking of the smallest components that enable the formation of large parts with minimum energy.

· Applicable Material Variety: Can be applied on ABS Plastic, Ceramic, Carbon-Fiber, Glass, Aluminum and many other materials.

· High Marking Speed: Focusing on a very strong focus, the laser delivers results up to dozens times faster than a traditional machine.

Marking without distancing material: Unlike processes such as laser engraving, this is a unique marking process that does not cause erosion on the material it is working on. Material erosion causes oxidation by heating the area it is aiming at. Provides a high resolution color change that leaves a permanent mark on the surface of the substrate.

one

3

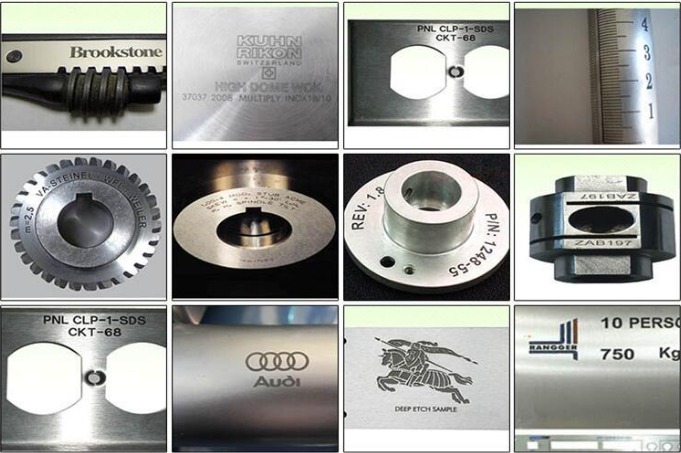

LASER MARKING // SAMPLE APPLICATIONS

Example applications

Fiber Laser Marking Machines are mainly used for marking plastic and metal surfaces. A special marking method is applied to each material to enable marking according to different material types.

Trackability with QR Code Marking

Marking mold part

Engraving

Evaporation with a very high energetic density lifts the material surface in the middle and creates a sharp linear impression. An additional color change to be obtained depending on the alloy or chemical composition may increase readability.

Hardening

This application is mainly high alloy, stainless steel and titanium. Partial heating changes an oxidation and the color of the surface without causing any damage.

Surface Lifting

The overlay is lifted by the laser to reveal the material underneath. Sample applications are made for day and night design of paint finishes, laser marking foils and control buttons.

Color Change

Especially applied on plastic. Different colors can be applied according to different mixtures of chemical material composition. It changes the color pigments and creates a marking by the application of gas bubbles. Dark markings can be created by carbonization.

foaming

The surface of the material is melted by the laser, the level is increased. When cooling starts, small gas bubbles are added to the incoming light, which is reflected by the reflected light.

Medical technology equipment

Marking for follow-up sterilization steps

Aluminum lettering plates

An automotive component marking

Production / Expiration date

Specifying the size of the medical industry

Plastic identification clips

Cable marking